Learning how to fix a slippery boat dock isn’t

a difficult project. A slippery wood boat dock is a dangerous place, but

it can be made safe and friendly to even bare feet by cleaning and applying Soft

Tread non-skid coating.

Most boat docks are made of 1” or 2” thick pressure

treated wood. Most pressure treated wood is dense and when the dock is new and

wet, it gets very slippery. Older pressure treated wood can be porous and prone

to the build-up of mold and mildew. When older docks get wet they can be very

slippery too. A slippery yacht dock is a dangerous boat dock!

This project is also a good chance to inspect your

dock and replace any rotten deck boards or to replace. Once any repairs are

complete, you’re ready to start the coating process.

The first step in making your slippery boat dock safe

is to get it spotlessly clean. A pressure washer is the best means of doing

this as it doesn’t require any detergent, chemicals or bleach to do a good job.

Use the largest possible pressure washer you can get as the little ones may not

do the job and will take a long time to get even mediocre results. The object

of pressure washing is not just to make the surface clean, it’s to remove ALL

dead wood fiber and rough up the surface to insure the best adhesion possible.

Take your time to really blow all the crud out of the wood and remove all the

loose wood fiber.

Once the dock is clean, it needs to dry out well.

Pressure treated wood tends to hold a lot of water so several days in the sun

is needed to dry the wood completely. While the wood is drying out, you can

check all the fastenings and secure the dock boards if they need another nail

or screw to make them hold fast to the underlying structure.

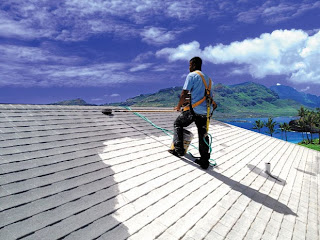

When the dock is dry, apply a coat of Soft Tread

Wood & Concrete Primer using a fluffy nap paint roller. The object is

to thoroughly saturate the dock boards without leaving any puddles on the

surface of the boards. If the dock boards are widely spaced rather than snug to

each other, you may want to put some plastic sheeting under the dock to catch

any spills to keep from contaminating the water. A piece of plastic sheet

about 6’ wide and 10’ long is perfect as long as you tie a piece of rope to

each corner. Then you can move the plastic along with you as you work from the

end of the dock toward shore.

When the Primer is dry, the Soft Tread can

be applied using either the 9” Texture roller or the 4” Roller. Be sure to use

the Texture Roller as a typical paint roller will not give the right type of

texture to the finished job. Mask off around any cleats or pilings. Apply the

Soft Tread in two moderate coats to achieve a spread rate of about 50 to 60

square feet per gallon for the total of both coats.

Allow at least 12 hours dry time before light foot

traffic and 48 hours before heavy traffic for best results.

Now you’ve changed a slippery boat dock into a safe

boat dock for your friends and guests.